Engineering students put their creativity and ingenuity on display this past Saturday at the Faculty of Engineering and Applied Science’s annual Capstone Project Day. Fourth-year students in Electronic Systems, Environmental Systems, Industrial Systems, Petroleum Systems, and Software Systems Engineering presented their projects and demonstrated how they’ve applied hands-on learning to real-world problems and challenges.

Alternative Design to Traditional Septic Systems for Ochapowace Nation

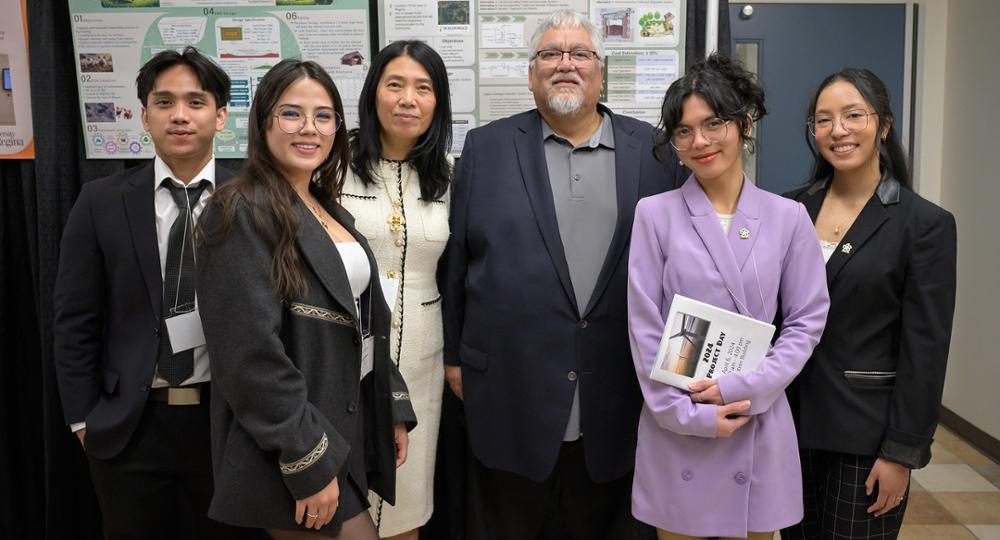

Environmental Systems Engineering students Ruth Mamani, Trisha Junco, Marianne Manaois, and EJ Cruz worked with the Ochapowace First Nation near Whitewood, Saskatchewan to design three wastewater systems that serve as alternatives to their existing traditional septic systems. Originally working with Ochapowace Nation on their water treatment system in summer 2023, when they returned to class in the fall, they found out that another group was working on something similar with another First Nation and had to pivot.

This project truly has the potential to revolutionize the farming industry and grain-grading process, as this level of precision has never been achieved before. — Brandon Hillbom, Software Systems Engineering student

“Most of our group had taken the course Advanced Water and Wastewater Engineering already, so Stephanie Young, our internal supervisor, felt we were well equipped to tackle a wastewater system issue,” says Mamani. “After talking with Deon Hassler, our external supervisor, we felt supported as he was aware of issues with the Ochapowace Nation’s wastewater system and ensured that we could put our expertise to work and continue our efforts with them – but with this new focus.”

The project aims to address the challenges faced by the Ochapowace Nation in effectively treating onsite wastewater, a crucial that issue that needed attention.

“The system will help reduce the wastewater contaminants within a shorter period of time and provide an effluent that is safe for discharge,” says Manaois. “We hope to implement this system across the province, especially in communities that heavily rely on septic systems and are in need of a more efficient way to treat their wastewater.”

Cruz says that the group hopes to not only improve the wastewater management in Ochapowace Nation, but also set a precedent for similar communities throughout Saskatchewan.

Throughout the project, the group learned about the direct links between sanitation and clean water and Ochapowace Nation’s economic development. When cast in that light, wastewater treatment systems become a higher priority when creating sustainable and thriving communities.

“We’d like to thank the Ochapowace Nation for allowing us to collaborate with the community – and for providing us access to their water treatment plant through an informative tour of the facility and for answering our many questions regarding concerns in their current septic system,” says Junco.

Intelligrain

Software Systems Engineering students Dillan Zurowski and Brandon Hillbom’s mobile app Intelligrain has transformative capabilities that could enable farmers to mitigate risks, negotiate fair contracts, and maximize the value of their crops, ushering in a new era of precision agriculture.

“Having grown up in Saskatchewan and having close relatives involved in the agriculture industry, we knew there were large gaps in the technology where we could find a way to assist farmers to improve their crop yields year after year,” says Zurowski. “We really wanted to centre our project around an idea that would bring meaningful change.”

The pair had heard about an opportunity to address these issues from Ground Truth Agriculture, a local company. Ground Truth Agriculture had developed cutting-edge machine vision and learning technology that take an image of a grain sample and analyze it to determine what the quality and underlying factors are. After discussing the project with Kyle Folk, Ground Truth Agriculture CEO, Zurowski and Hillbom determined there was an opportunity to support Ground Truth Agricuture’s vision by developing a mobile app for commercial farmers.

Currently, farmers have a tiny sample of grain taken from a massive grain bin. This sample determines what the grain bin is worth and it is assigned a grade (1, 2, 3, feed or sample). This generalized process essentially forces farmers to guess the quality of their grain as they make contracts before, during, and after harvest based on historical analysis of their fields.

“We have had farmers tell us that deciding on a contract for a specific grade of grain is essentially being blindfolded and made to throw darts at a dart board,” says Zurowski. “Our mobile app, Intelligrain, gives the power back to farmers. Intelligrain provides real-time grade information to farmers and combine drivers so that they know how each area of their field is graded.”

Additionally, Intelligrain allows farmers to access insights, including what contributing factors are causing the grade to be lower such as damage, frost, mould or protein. They are also able to filter the map to better visualize problem areas in their field, export the map to overlay with other data they have, manage their team members, and view the sample images with annotations of the problematic grains.

“This project will allow farmers to negotiate fair contracts and improve the quality and yield of their crops year after year by accessing data that they have never had access to before,” says Hillbom. “It truly has the potential to revolutionize the farming industry and grain-grading process, as this level of precision has never been achieved before.

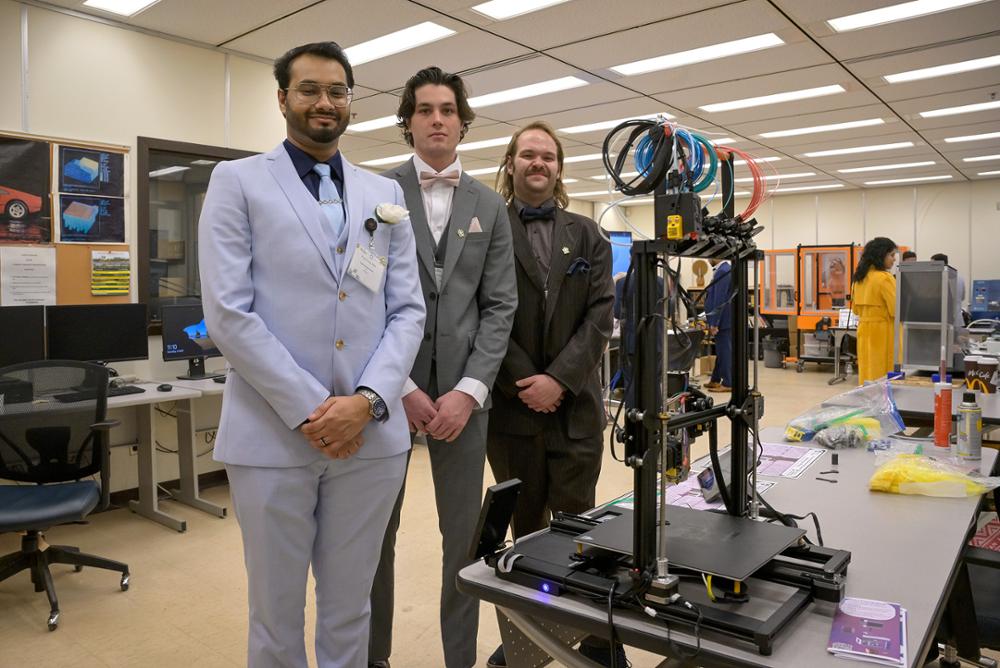

Anti-ooze Valve System for Pellet-based, High-flow Extrusion 3D Printing

Fourth-year Industrial Systems Engineering students Daniel Slogoski, Teagen Biette, and Danish Hasan addressed a critical flaw in pellet-based 3D printing processes with their project Anti-ooze Valve System for Pellet-based, High-flow Extrusion 3D Printing.

The flaw – the unwanted oozing of molten material through the nozzle during temporary stops in printing – affects the integrity of the print structure and overall print quality.

“The idea for our project comes from one of the few drawbacks of pellet-based printing, which is that there is no way to prevent melted pellets from flowing out of the nozzle during non-printing movements,” says Biette.

The team focused on designing and developing a valving system to mitigate the oozing issue by temporarily redirecting the material flow to a designated storage reservoir, sized appropriately to accommodate anticipated material volumes. This reduces the need for frequent manual intervention.

“Our project is aimed at solving a very real problem,” says Slogoski. “We knew that a mechanism to prevent the seepage of molten material from the nozzle would be huge for pellet-based printing, greatly affecting the quality and precision of prints.”

The design consists of a strategically positioned, two-channeled shaft sliding into a prudently dimensioned heater block that is integrated into the printing assembly. During pauses in printing, the valve is programmed to actuate, diverting the molten material into the custom-built reservoir.

Interested in presenting your own Capstone Project one day? Check out the different programs offered by the Faculty of Engineering and Applied Science!

“When we started this project, we all knew next to nothing about the world of 3D printing,” says Hasan. “Now, after a steep learning curve, we are working on a project with the potential to revolutionize 3D printing.”

With the wide variety projects at this year’s event and the revolutionary nature of the students’ solutions to real-world problems, Engineering Project Day is a fantastic example of what U of R Engineering students are capable of – post-grad, and beyond!

Banner Photo: (L to R) Environmental Systems Engineering students Ruth Mamani, Trisha Junco, EJ Cruz, and Marianne Manaois at Engineering Project Day. Credit: University of Regina Photography.

About the University of Regina

2024 marks our 50th anniversary as an independent University (although our roots as Regina College date back more than a century!). As we celebrate our past, we work towards a future that is as limitless as the prairie horizon. We support the health and well-being of our 16,700 students and provide them with hands-on learning opportunities to develop career-ready graduates. Our research enterprise has grown to include 21 research centres and 12 Canada Research Chairs and brings in more than $51.2 million in funding annually. Our campuses are on Treaties 4 and 6 - the territories of the nêhiyawak, Anihšināpēk, Dakota, Lakota, and Nakoda peoples, and the homeland of the Michif/Métis nation. We seek to grow our relationships with Indigenous communities to build a more inclusive future.

Let’s go far, together.