When you hear “3D printing,” you might picture a small machine on a desk making colorful trinkets. But in a lab at the University of Regina, that idea is being completely reshaped. Here, 3D printing isn’t just a hobbyist’s tool; it’s the foundation for building custom medical devices, pioneering sustainable housing, and engineering the future of high-performance industries.

Welcome to the Additive Manufacturing Research Lab (AMRL), the only dedicated 3D printing research lab in Saskatchewan. Led by Mohammad Khondoker, an assistant professor in the Faculty of Engineering and Applied Science, the lab is a hub of innovation where the boundaries of manufacturing are redrawn daily.

We’re not limited by what commercial systems can do; we create new capabilities. — Dr. Mohammad Khondoker, assistant professor, Faculty of Engineering and Applied Science, University of Regina

The AMRL advantage: More than a lab, an innovation engine

What makes the AMRL unique isn’t only its status as a provincial first, but also its hands-on philosophy. While most labs use commercial 3D printers as “black boxes,” hoping for the best, Dr. Khondoker and his students build and modify their own.

“We must understand and control every variable in the process,” says Khondoker, explaining that this “guinea pig” approach means that when industry partners bring unconventional materials or extreme requirements, the lab can redesign the printing process to accommodate them. “We’re not limited by what commercial systems can do; we create new capabilities.”

This spirit of innovation is what enabled Khondoker to build the research program from the ground up. Arriving at the University without a single 3D printer, he secured an NSERC Discovery Grant that provided the essential funding to establish and grow the first additive manufacturing-focused research lab in Saskatchewan.

Solving real-world problems

The lab’s innovations are not just theoretical; they are providing tangible solutions for healthcare and industry. One of the most impactful projects is the creation of custom-fit orthotics.

“Most traditional orthotics are ‘one-size-fits-all,’” says Khondoker. “We can design orthotics to match the specific needs of each person’s body.”

Using a specialized polymer, the lab recently 3D-printed an orthotic that feels as soft as flesh but is strong enough to support an injured hand. This personalized approach enhances comfort and mobility in ways standard devices cannot.

Redefining what’s possible. The AMRL uses advanced 3D printing to solve challenges across industries. Pictured (left to right): a pink colored lower-leg prosthetics model showing internal structural density (left), a grey lattice-patterned orthotics model (centre), and a translucent white cylindrical heat exchanger prototype with complex internal channels (right). Photo Credit: University Communications and Marketing

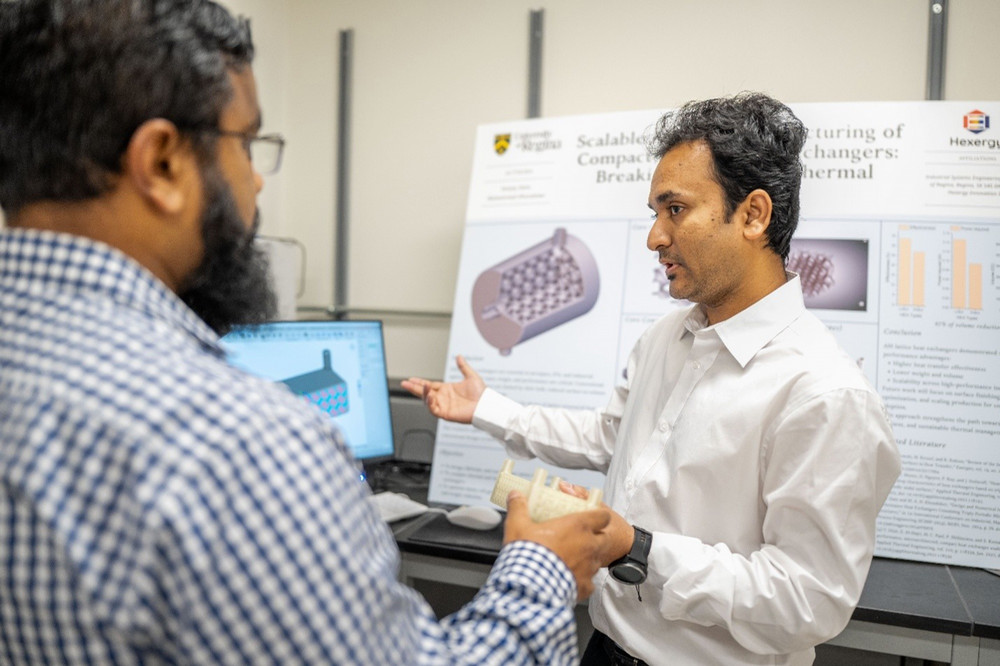

The lab is also a gamechanger for industries such as aerospace and automotive. The team has developed a new type of heat exchanger using metal 3D printing that outperforms traditional models while taking up less space. The breakthrough is its internal “lattice” structure, a 3D honeycomb impossible to create with conventional methods. This allows engines and cooling systems to operate more efficiently, reducing fuel consumption and emissions, a critical advantage in applications where weight and space are at a premium.

Students as innovators and entrepreneurs

MASc student Sanjoy Dam (right) demonstrates the intricate design of a lattice-based 3D printed heat exchanger to a colleague. Dam's research focuses on creating high-efficiency thermal management solutions that are impossible to manufacture with traditional methods. Photo Credit: Mohammad Khondoker

The AMRL is a testament to the U of R’s commitment to experiential learning, where students are not just assistants but primary investigators.

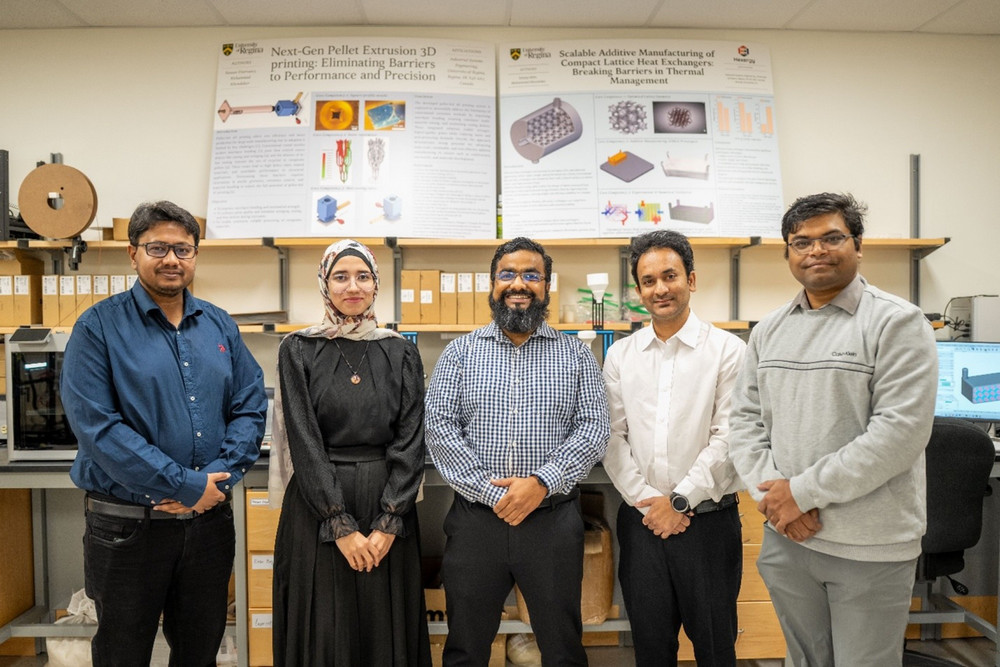

“Each graduate student takes ownership of a unique research thrust,” Khondoker notes proudly, highlighting how students lead and thrive, fostering trust in the University’s commitment to nurturing future innovators.

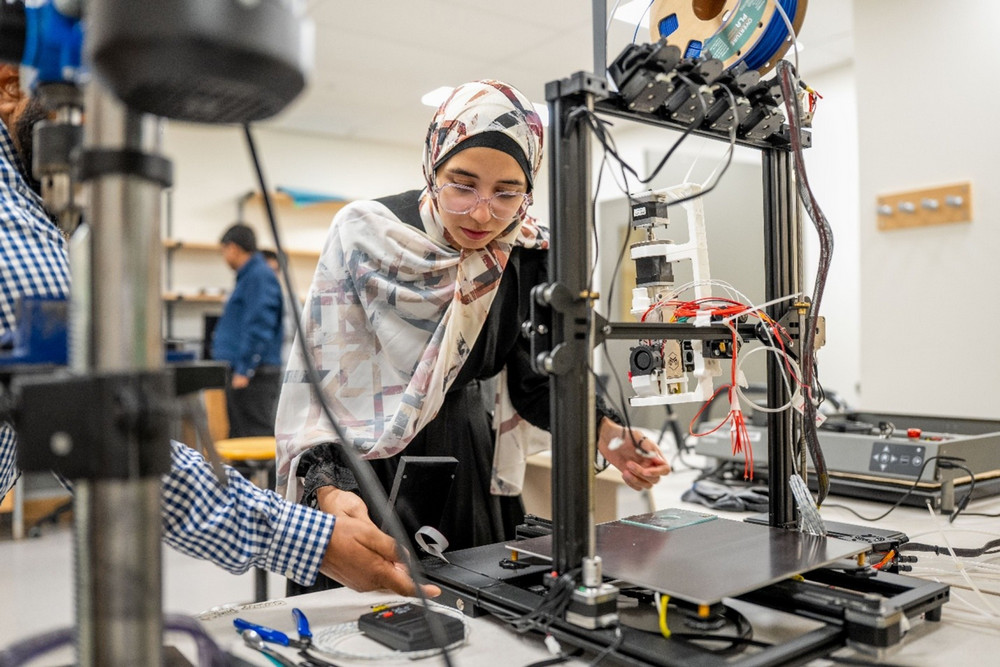

Rawan Elsersawy, a PhD student in the lab, is a prime example.

“Working in this lab has allowed me to connect theory directly to practice,” says Elsersawy. “You are not just learning concepts in isolation. You are applying them, seeing where they succeed, and understanding where improvements are needed.”

Rawan Elsersawy, a PhD student in the Additive Manufacturing Research Lab (AMRL), tests the integration of a custom-designed advanced extruder system with an existing 3D printer, part of her work to develop large-format polymer printing capabilities. Photo Credit: Mohammad Khondoker

Elsersawy is currently developing a large-format polymer 3D printer with unique capabilities that go far beyond what’s commercially available. Unlike most printers that rely on filaments, this system uses raw pellets and can print multiple polymers with complete blending control. It achieves extremely high print speeds, measured in kilograms per hour rather than grams, and features a custom-designed nozzle for exceptionally smooth surface finishes. The innovation has already led to the launch of a startup to commercialize the technology.

In fact, the AMRL has launched two spinoff companies led by graduate students: Hexergy Innovations Inc., which specializes in 3D-printed heat exchangers, and another, currently in the process of incorporation, that will commercialize next-generation polymer 3D printers, exemplifying how students translate research into industry impact and entrepreneurial success.

A catalyst for Saskatchewan’s bright future

While Saskatchewan may be seen as behind in advanced manufacturing, the AMRL’s work positions the province to become a future leader, inspiring optimism about regional growth and innovation.

“Our lab is well-positioned to contribute meaningfully,” says Khondoker. “For instance, through 3D printing research focused on critical Small Modular Reactor (SMR) components such as high-performing heat pipes. By advancing this work, we can help establish Saskatchewan as a pioneer in nuclear innovation.”

The faces of future innovation. In the Additive Manufacturing Research Lab (AMRL), students are empowered to act as primary investigators on ground-breaking projects. Pictured here is the team driving this research: (from left) MASc student Mohammad Ruhul Amin, PhD student Rawan Elsersawy, Principal Investigator Mohammad Khondoker, MASc student Sanjoy Dam, and MASc student Md Rashid Alam. Photo Credit: Mohammad Khondoker

From custom-fit medical devices to more efficient industrial parts and a more sustainable future for the province, the work happening at the AMRL is a powerful example of how research at the U of R is solving real-world problems. It’s a place where students are not just preparing for the future; they are actively building it.

Don’t just get a degree, build a career. Discover our programs in the Faculty of Engineering and Applied Science and find out how our commitment to experiential learning can help you launch your future today. Learn More at the Faculty of Engineering & Applied Science.

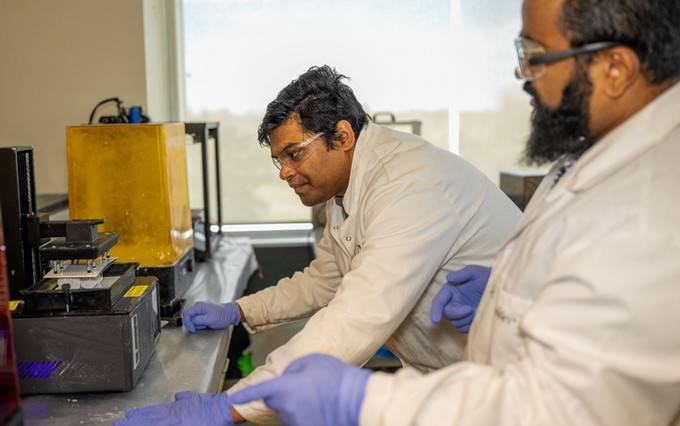

Banner Photo: Hands-on discovery. MASc student Md Rashid Alam (left) explains the properties of a 3D-printed ceramic Waveguide Insert to Professor Mohammad Khondoker (right). These specialized components require precise material handling and custom print settings developed directly in the lab. Photo Credit: Mohammad Khondoker

About the University of Regina

At the University of Regina, we believe the best way to learn is through access to world-class professors, research, and experiential learning. We are committed to the health and well-being of our more than 16,600 students and support a dynamic research community focused on evidence-based solutions to today’s most pressing challenges. Located on Treaties 4 and 6—the territories of the nêhiyawak, Anihšināpēk, Dakota, Lakota, and Nakoda peoples, and the homeland of the Michif/Métis nation —we honour our ongoing relationships with Indigenous communities and remain committed to the path of reconciliation. Our vibrant alumni community is more than 95,000 strong and enriching communities in Saskatchewan and around the globe.

Let’s go far, together.