U of R Stories

Honouring Indigenous Storytelling Month

Students Pitch Big Ideas at Inaugural Saskatchewan Hackathon

Recent Posts

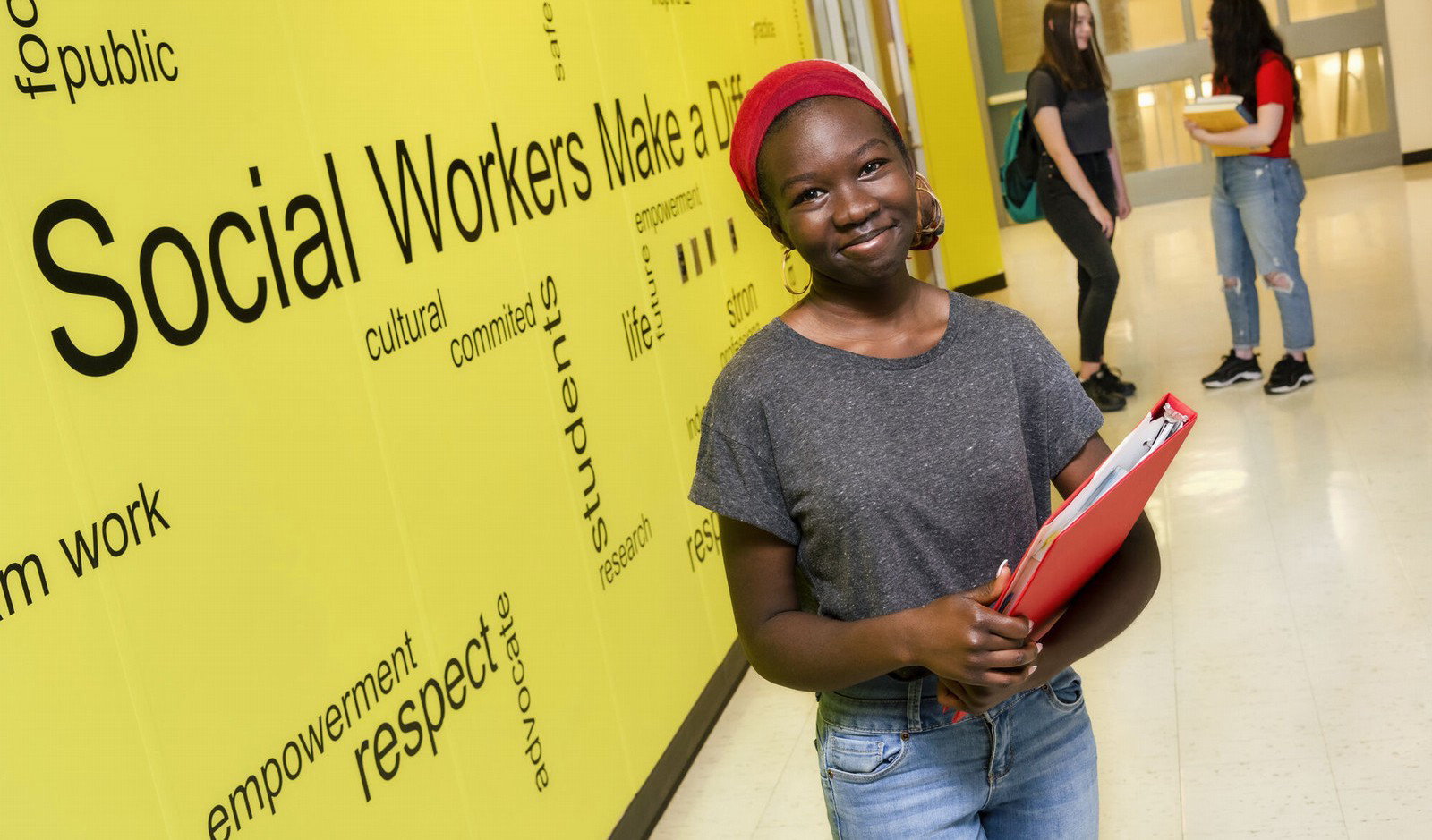

Building a New Chapter in Saskatoon

The Saskatoon-based Social Work and Nursing faculties are moving out of Innovation Place, their longtime home, to a new space designed just for them.

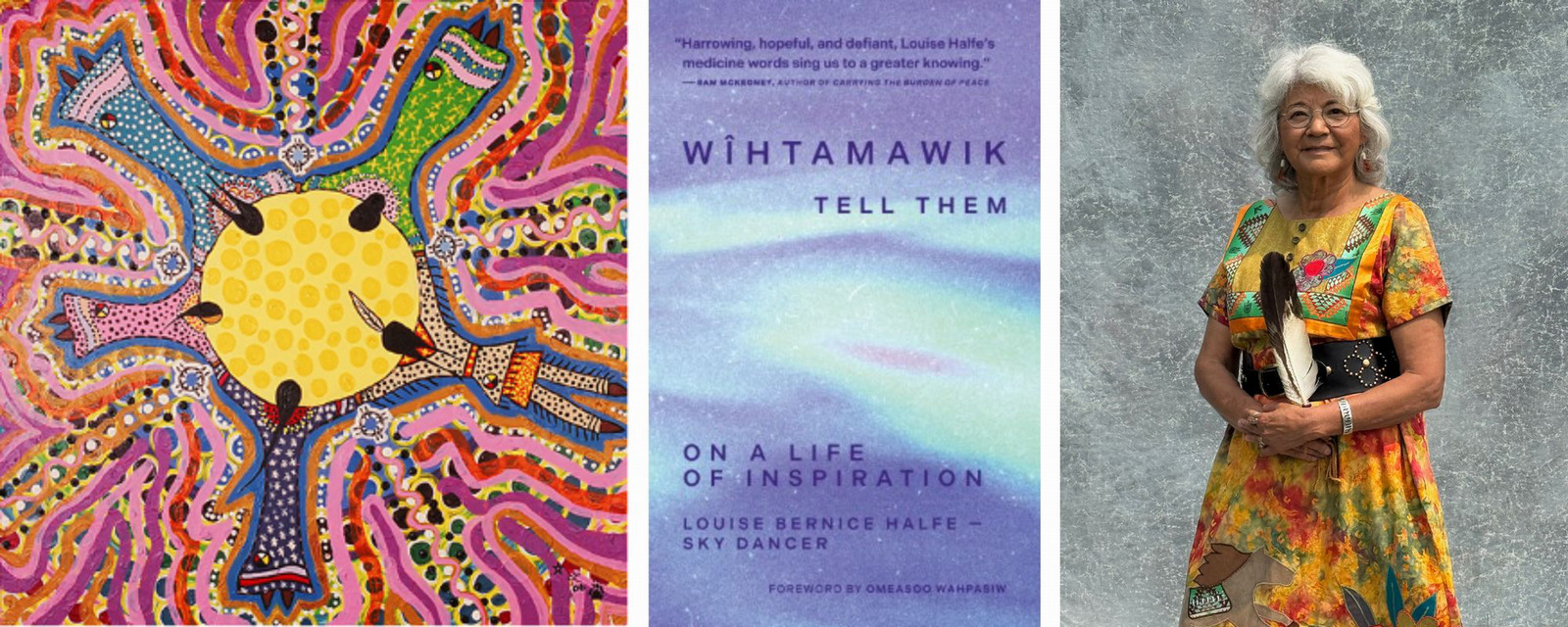

Honouring Indigenous Storytelling Month

Join the Archer Library and U of R Press for a book launch and other related events that celebrate First Nations, Métis, and Inuit history,...

Students Pitch Big Ideas at Inaugural Saskatchewan Hackathon

65 undergraduate students from across the province came together at the University of Regina for the first Saskatchewan Crown Sector Hackathon,...

Where Paws Meet Purpose

How canine-assisted therapy helps federal prisoners build trust and connection while giving U of R students a transformative hands-on experience.

Top 5 Reasons to Study at the U of R: Where Ambition Meets Opportunity

From world-class research to hands-on experience, discover why students from more than 100 countries are choosing the University of Regina to...

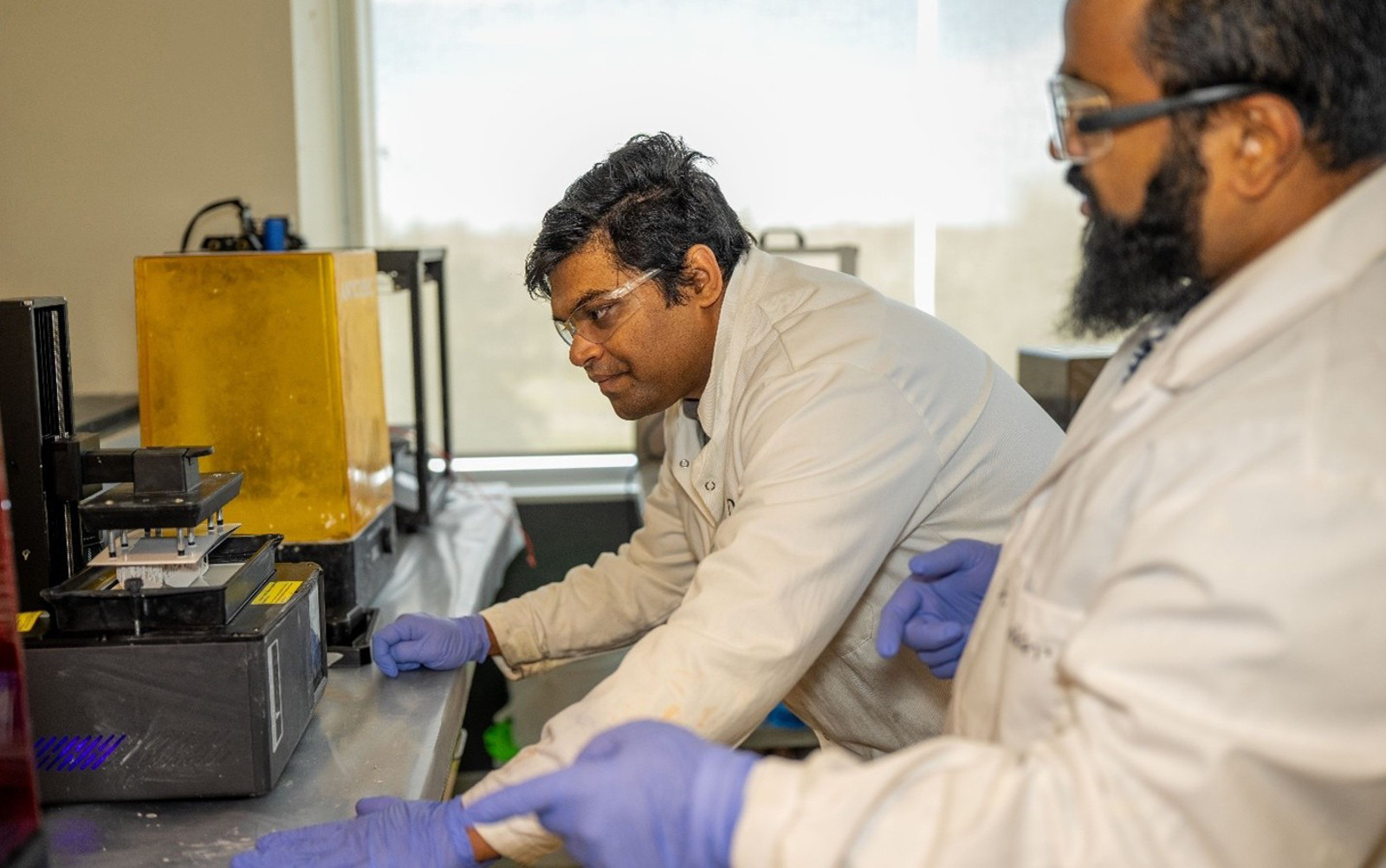

3D Printing: A Promising Frontier for Saskatchewan Research

Pioneering innovations in healthcare, industrial parts, and affordable housing position the U of R as a leader in advanced 3D technology.

In the Loop

As Saskatchewan moves toward developing zero-emission nuclear power through small modular reactors (SMRs), the need for homegrown research...

Check in with Your Health and Wellness this Winter Semester

Not sure what kind of support you need this semester? Our health and wellness check-in can help point you in the right direction.

Year in Review: Top U of R Stories from 2025

Check out the exciting and transformative ways that our campus community drove change, celebrated milestones, and forged stronger partnerships in...

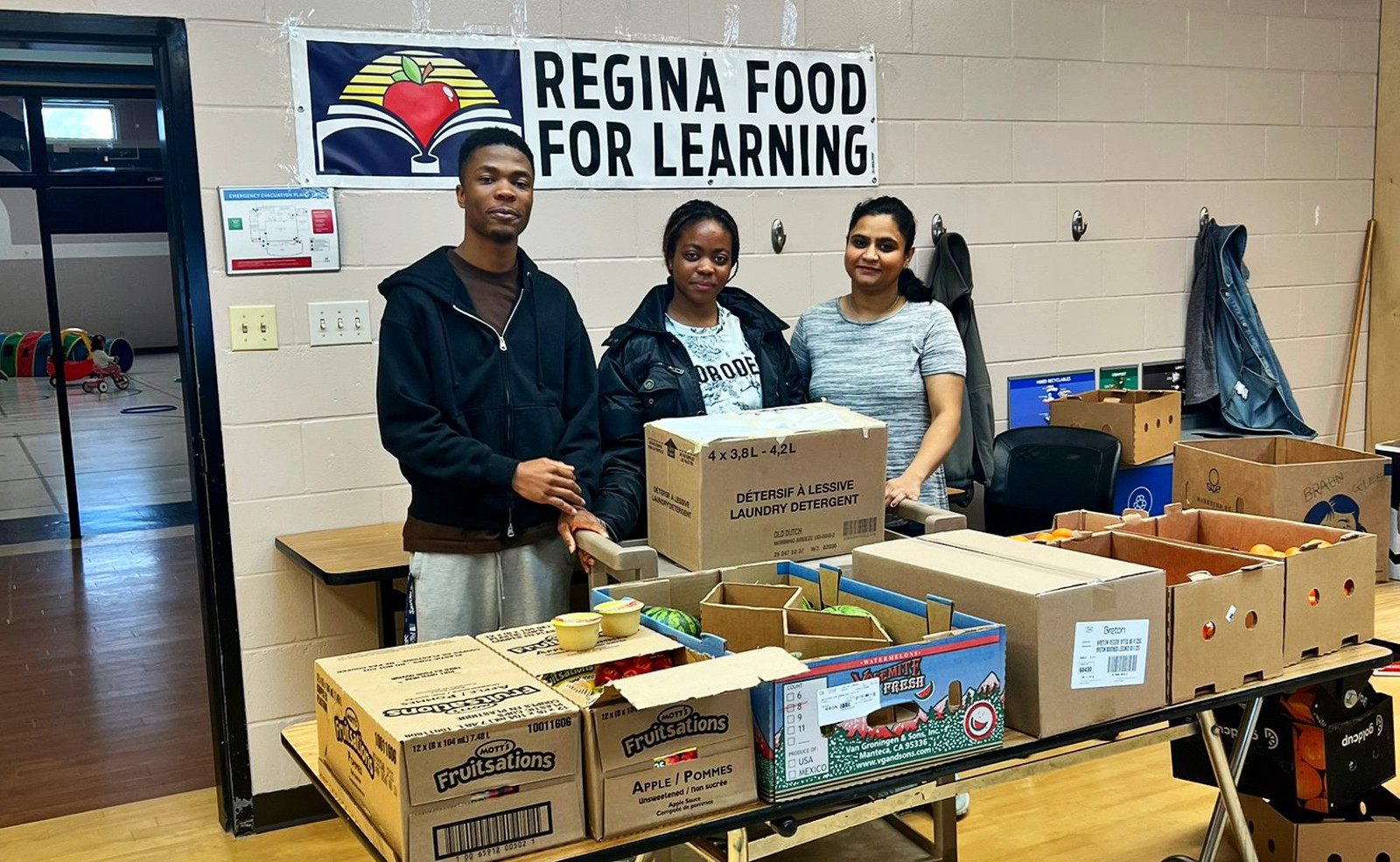

U of R Students in the Spirit of Giving All Year Long

Sometimes the most meaningful gifts are not wrapped, they are baked, delivered, and shared from the heart.