U of R Stories

U of R Engineers Engineer a Greener, Smarter Future

Recent Posts

Arts Education Creates Stronger Classroom Communities

U of R Arts Education students share how the arts are transforming teaching and helping students find their voices.

Knapp Rink on the Button for Another Brier Appearance

The connections between teammates headed to the Montana’s Brier run deep. Not only are they some of Canada’s most talented curlers...

U of R Engineers Engineer a Greener, Smarter Future

U of R Engineering Researchers are tackling critical energy challenges, from using oilfield waste for cleaning produced wastewater to ensuring...

Take a Skull Tour with U of R Science Students

Ever held a shark jaw? U of R biology students invited the public to step into their lab for a Skull Tour.

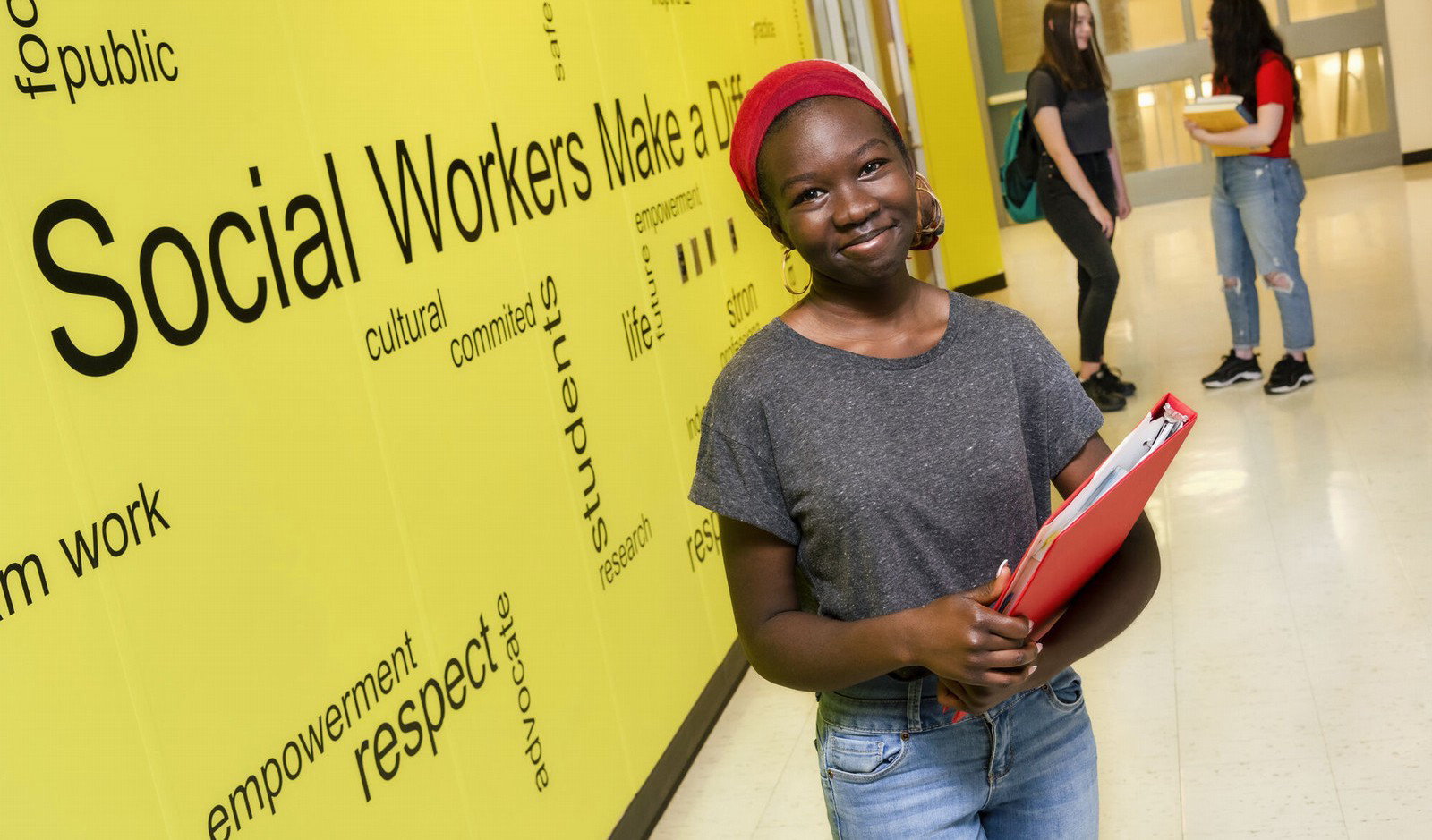

Building a New Chapter in Saskatoon

The Saskatoon-based Social Work and Nursing faculties are moving out of Innovation Place, their longtime home, to a new space designed just for them.

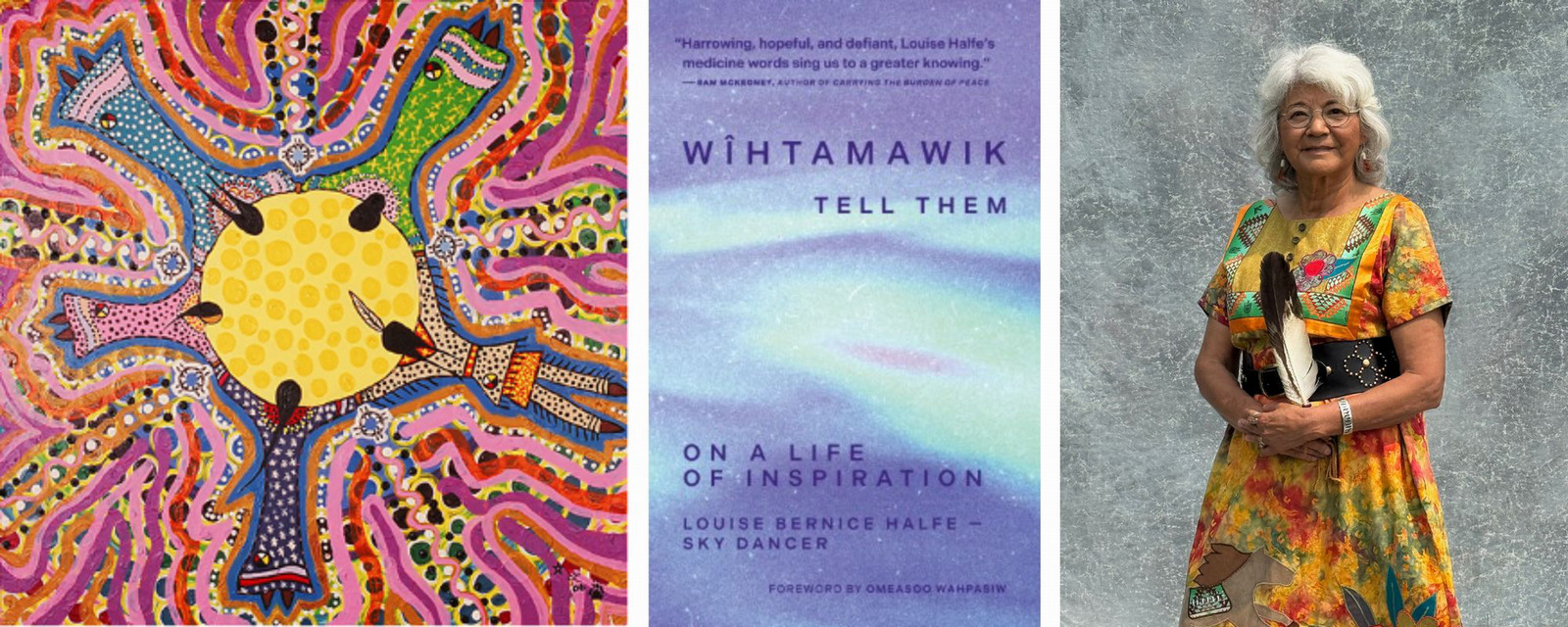

Honouring Indigenous Storytelling Month

Join the Archer Library and U of R Press for a book launch and other related events that celebrate First Nations, Métis, and Inuit history,...

Students Pitch Big Ideas at Inaugural Saskatchewan Hackathon

65 undergraduate students from across the province came together at the University of Regina for the first Saskatchewan Crown Sector Hackathon,...

Where Paws Meet Purpose

How canine-assisted therapy helps federal prisoners build trust and connection while giving U of R students a transformative hands-on experience.

Top 5 Reasons to Study at the U of R: Where Ambition Meets Opportunity

From world-class research to hands-on experience, discover why students from more than 100 countries are choosing the University of Regina to...

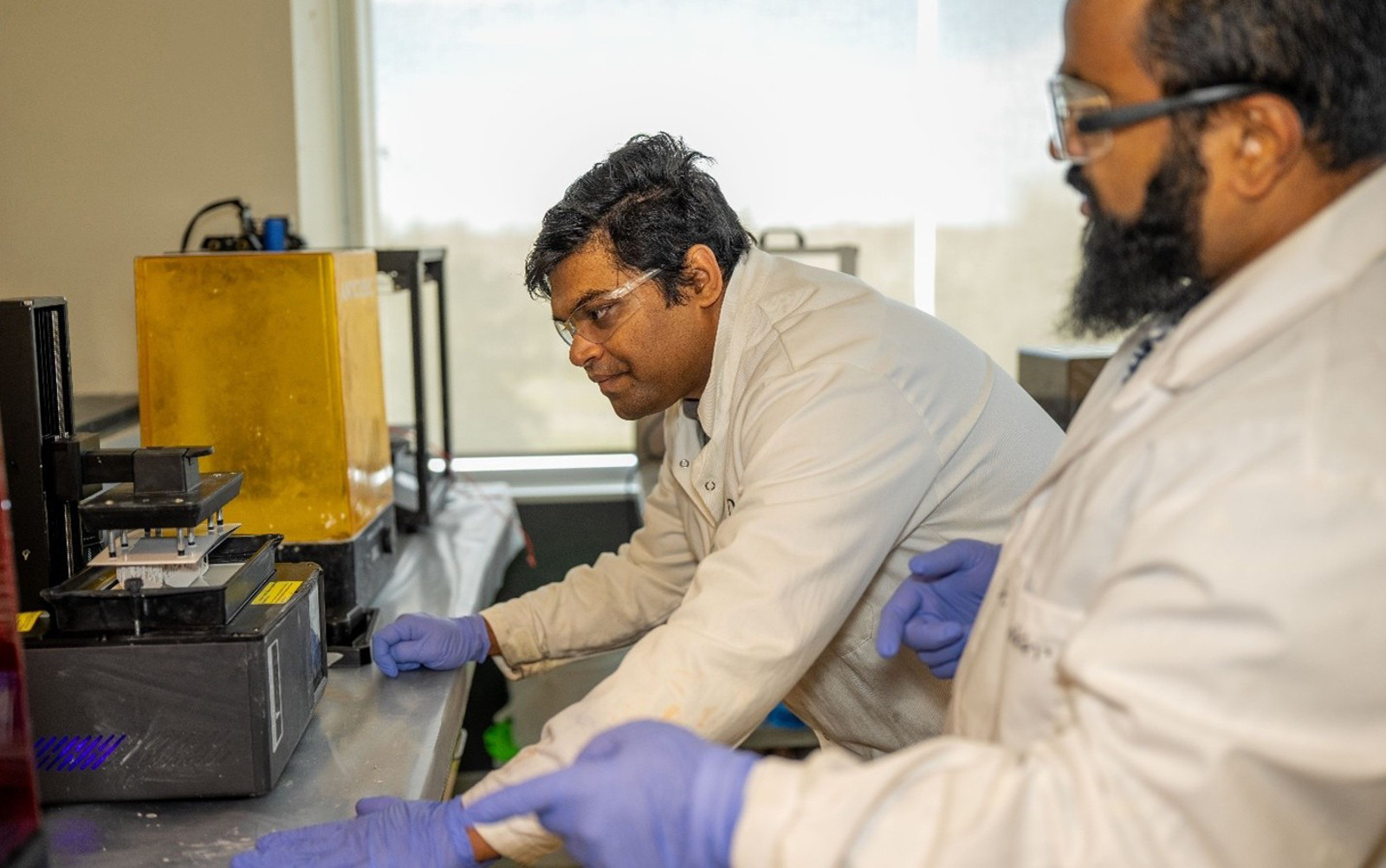

3D Printing: A Promising Frontier for Saskatchewan Research

Pioneering innovations in healthcare, industrial parts, and affordable housing position the U of R as a leader in advanced 3D technology.